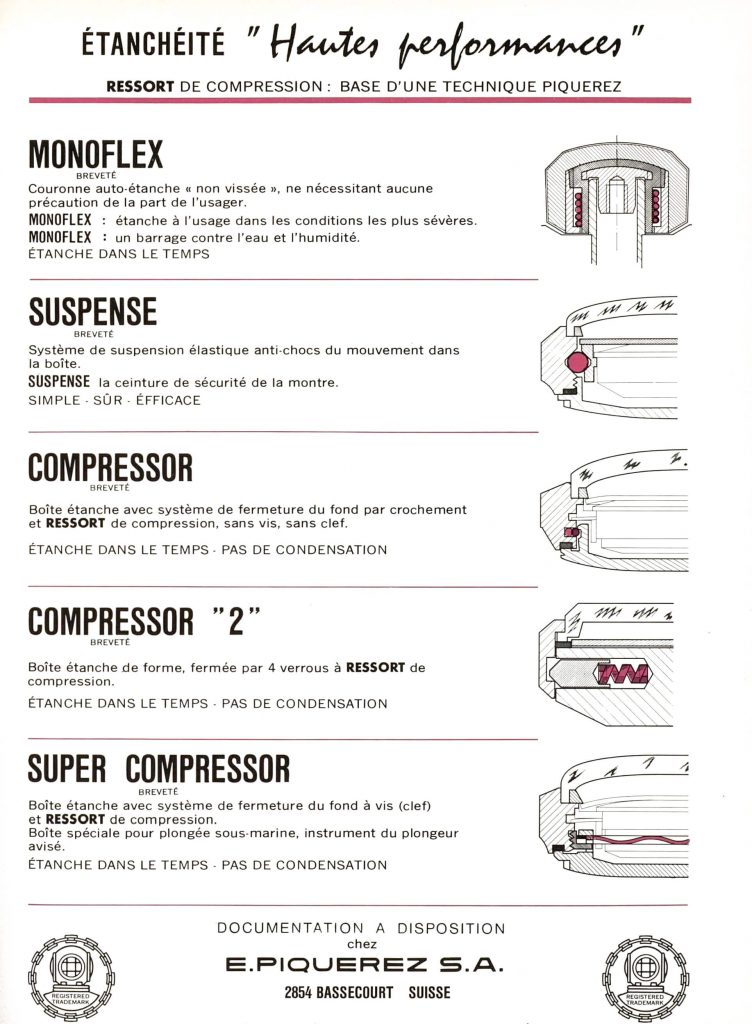

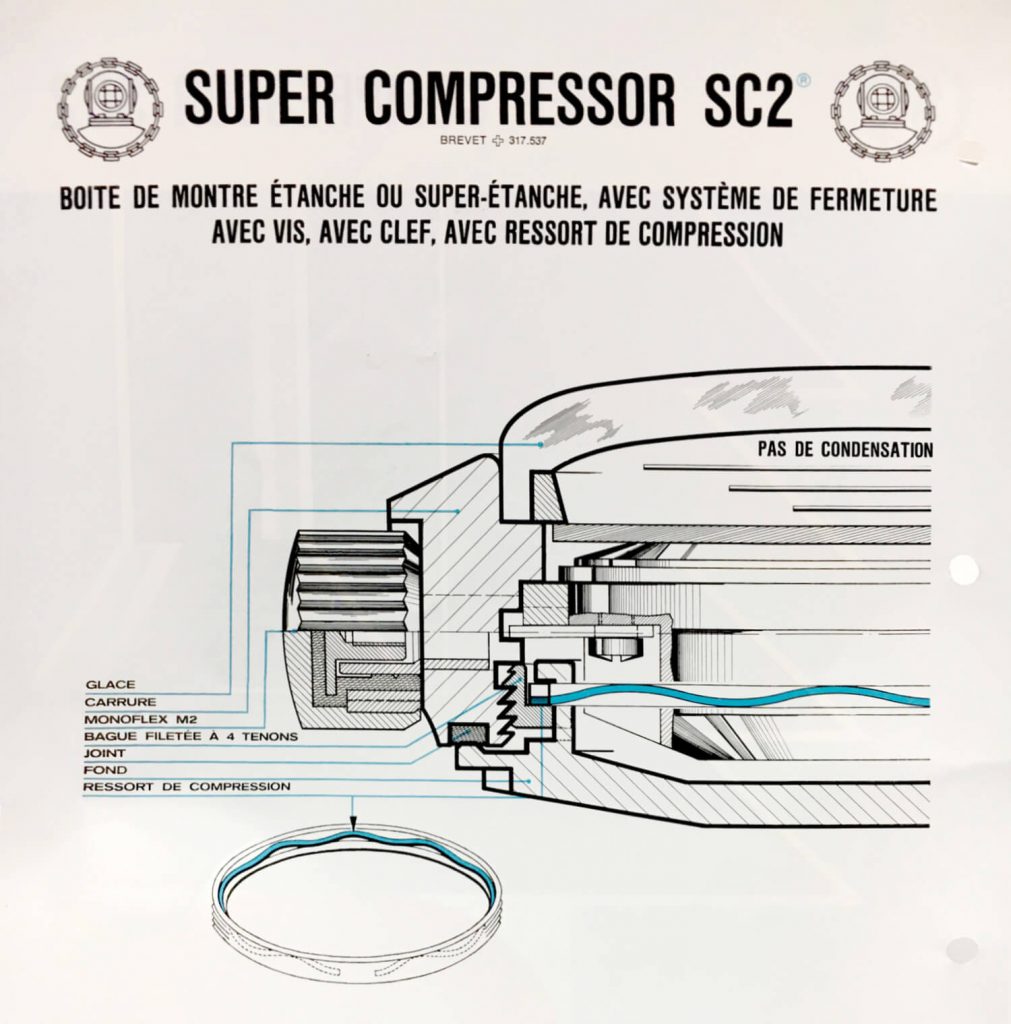

The technology behind the super compressor was introduced in the 1950s. At that time, it was not easy to design and build a water-resistant watch, especially for mass production. The sealing materials were not yet as reliable as today, and some materials we use nowadays were not even invented or developed to sufficient quality standards.

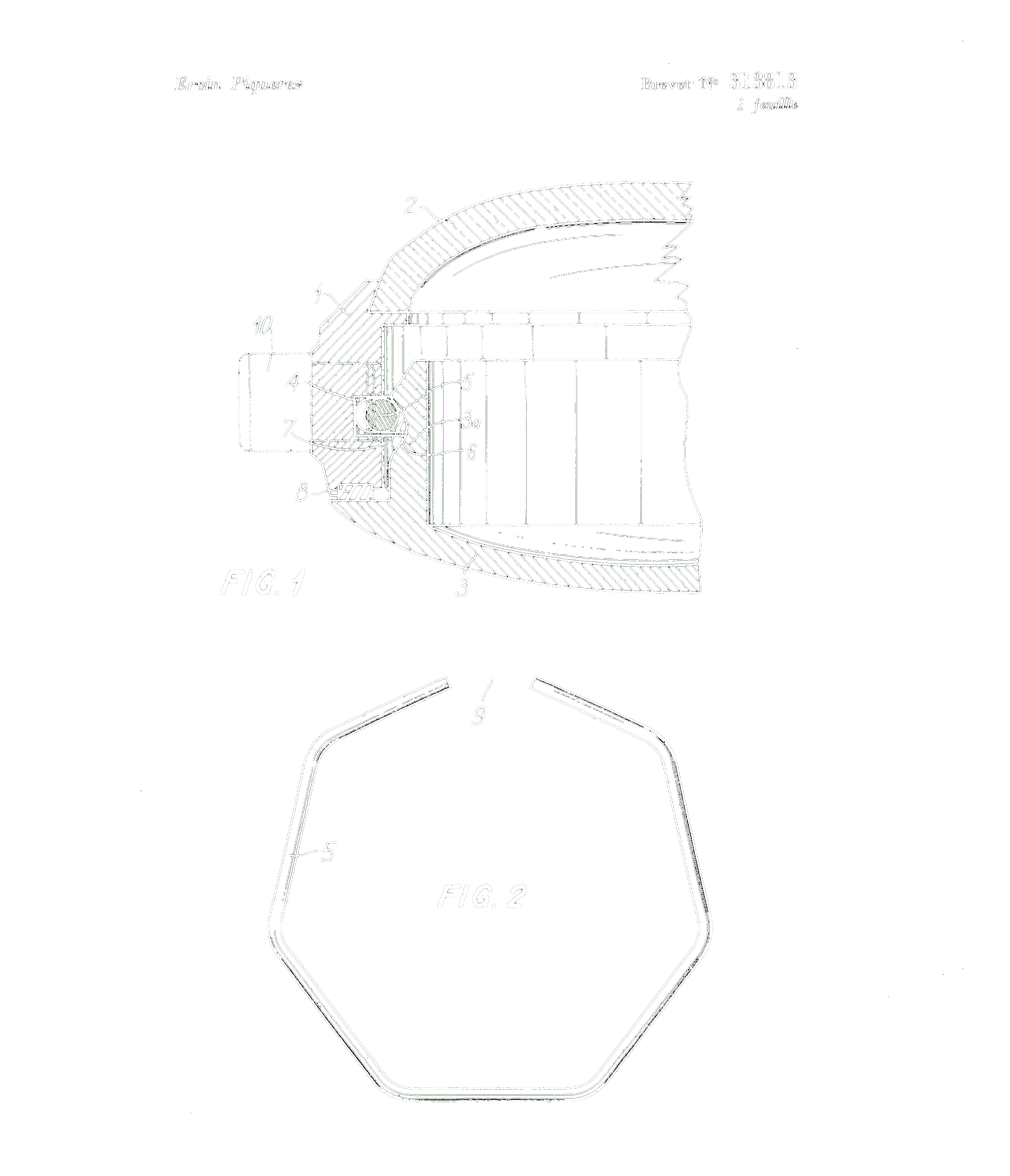

So, watch brands had to be very inventive to achieve water-resistance. A company that was ahead of its time, was Ervin Piquerez SA, also known as the abbreviation EPSA to watch connoisseurs. The designers and engineers of the company, which was at some point in time the largest manufacturer of watch cases in the world and worked for all the big watch brands, had several groundbreaking ideas during the 1950s and addressed the problem of achieving water tightness in many clever ways.

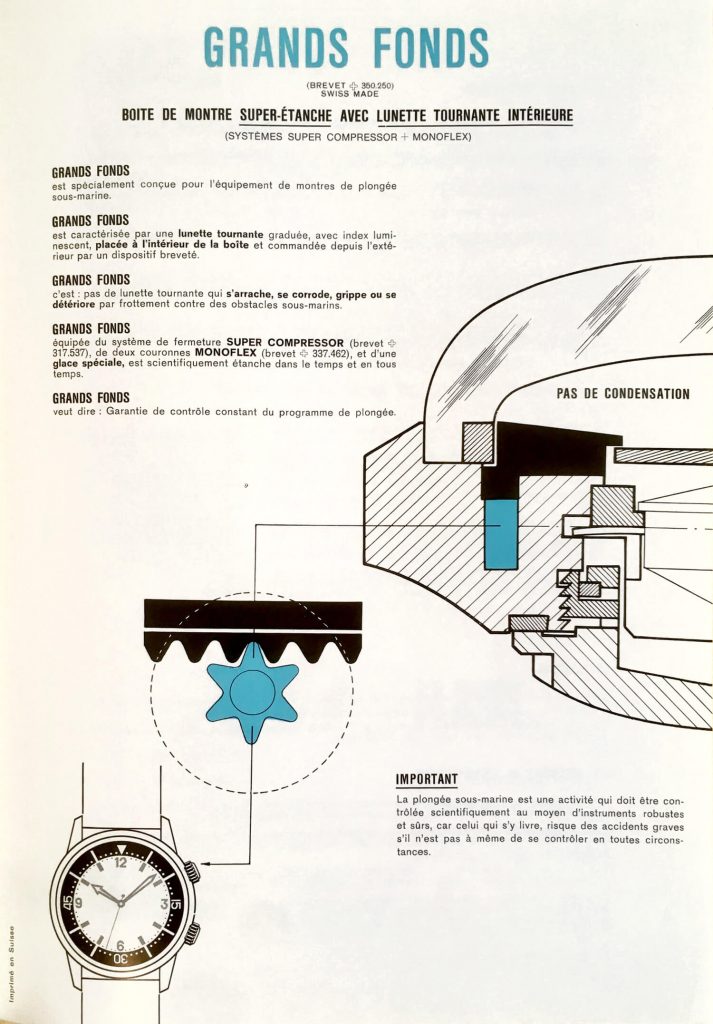

The (super) compressor technology

Up till the early 1950s, sealing materials were usually not of the quality and characteristics that were needed to withstand rising water pressure. In many cases, the materials would deform and make the sealing pressure fade over time, resulting in leakages. The technicians from EPSA had a brilliant idea how to solve this problem: